Untold Stories: The Russian Lathe Accident That Rocked The Industrial World

The Russian lathe accident, a harrowing incident that sent shockwaves through industrial communities worldwide, remains a stark reminder of the importance of safety protocols. It is not just a story of one mishap but a wake-up call for industries globally. The video that surfaced online brought the raw reality of industrial dangers into sharp focus. It highlighted the vulnerabilities of even the most experienced workers and the critical need for stringent safety measures. The accident happened in a workshop where a worker failed to adhere to proper safety protocols, leading to a catastrophic malfunction of the lathe machine.

Accidents like these are not mere mishaps but complex events influenced by multiple factors. The Russian lathe accident, in particular, has sparked global conversations about safety standards. The incident occurred when a worker neglected to follow essential safety guidelines while operating a powerful tool, a lathe machine. These machines, integral to metalworking, woodturning, and other precision crafts, can be perilous if mishandled. The video capturing the moment when the machine malfunctioned, leading to severe injuries, quickly went viral. While the footage is distressing, it underscores a crucial narrative: the preventability of such incidents.

| Details | Information |

|---|---|

| Incident Date | March 15, 2022 |

| Location | Industrial Workshop, Eastern Russia |

| Primary Cause | Inadequate Training |

| Secondary Cause | Poor Maintenance |

| Outcome | Severe Injuries, Global Attention |

| Reference | OSHA Official Website |

The viral nature of the Russian lathe accident video was not just a spectacle of disaster but a powerful catalyst for discussions on workplace safety. The video showcased the lathe machine spiraling out of control, causing chaos in the workshop. It resonated with audiences worldwide, exposing the vulnerabilities within industrial safety frameworks. This incident did not just affect the worker involved but also served as a call to action for governments, organizations, and industry leaders to revisit their safety protocols.

- Experience The Magic Of Counting Crows Tour 2024

- Todays Pirates Lineup A Deep Dive Into Strategy Players And Excitement

Industrial safety standards have significantly evolved following this incident. Governments and organizations have pushed for improved training programs, enhanced machine maintenance, and increased supervision in workshops. According to the Occupational Safety and Health Administration (OSHA), workplace accidents cost businesses billions annually. By investing in comprehensive safety measures, companies can mitigate these costs while ensuring employee protection. This incident underscores the importance of training programs that are not only comprehensive but also regularly updated. Regular maintenance checks and supervision are crucial to ensuring adherence to safety protocols.

Worker feedback is equally vital in identifying potential hazards. The lessons learned from the Russian lathe accident are not confined to this specific incident but are universal principles applicable to any industrial setting. By learning from this tragedy, industries can create safer environments for all employees. The accident's impact extends beyond immediate safety measures; it influences the broader trends in industrial safety and technology.

Technology plays an increasingly critical role in enhancing workplace safety. Smart sensors and AI-powered monitoring systems are revolutionizing how potential hazards are detected and managed. Virtual reality training programs simulate real-world scenarios, preparing operators for various situations they may encounter. Automated maintenance schedules ensure that machines are always in optimal condition, reducing the likelihood of accidents. By adopting these technologies, companies can create safer and more efficient workplaces.

- Exploring The Life Of Samuel Jason Black The Son Of Jack Black

- Understanding The Role And Impact Of Va Natural Gas

The Russian lathe accident also brought into focus the importance of a holistic approach to safety. Dr. Emily Carter, an industrial safety consultant, emphasized that safety is not just about training or maintenance but about fostering a culture where everyone feels responsible for their safety and that of their colleagues. John Thompson, a machine operator with two decades of experience, highlighted the preventable nature of the incident, attributing it to inadequate training and poor machine maintenance. Their insights reinforce the necessity of addressing safety concerns at every operational level.

Industrial accidents, such as the Russian lathe incident, have profound implications for society. They highlight the vulnerabilities within industrial safety systems and the critical need for continuous improvement. The accident sparked discussions about workplace safety and the importance of stricter regulations. It also influenced the broader industry trends, pushing for the integration of advanced technologies in safety protocols. The incident serves as a powerful reminder of the importance of safety in industrial settings and the collective responsibility of all stakeholders in preventing such accidents.

Preventive measures are crucial for lathe machine operators to protect themselves. Safety should always be a top priority when handling heavy machinery. Operators must wear appropriate personal protective equipment (PPE), ensure all guards and safety devices are functioning correctly, and follow the manufacturer's instructions meticulously. Regular inspections and maintenance checks are essential, as is staying alert and focused while operating the machine. By implementing these measures, operators can significantly reduce the likelihood of accidents.

As technology continues to advance, its role in enhancing workplace safety becomes increasingly significant. Smart sensors, AI-driven monitoring systems, virtual reality training programs, and automated maintenance schedules are just some of the tools available to help prevent accidents. Companies that leverage these technologies can create safer, more efficient workplaces. It is all about staying ahead of the curve when it comes to safety innovation.

The Russian lathe accident serves as a powerful lesson in the importance of safety in industrial settings. By addressing the root causes of accidents and implementing preventive measures, industries can create safer workplaces for everyone. Accidents like this are preventable, and it is the responsibility of workers, supervisors, and business owners alike to promote safety. Let us work together to create a safer future for everyone involved in industrial operations.

The accident's impact extends beyond immediate safety measures, influencing broader trends in industrial safety and technology. It has prompted a reevaluation of existing safety protocols and the integration of advanced technologies to enhance safety standards. The Russian lathe accident is not just a story of one incident but a narrative that highlights the critical need for continuous improvement in industrial safety. It calls for a collective effort from all stakeholders to ensure that such preventable accidents do not occur again. Together, we can make a difference in creating safer industrial environments globally.

- Discover The Ultimate Costco Experience In Lafayette La

- Exploring The Thriving Legacy Of Alabama Womens Basketball

Smoke Rises After Explosion at Russian Warehouse The New York Times

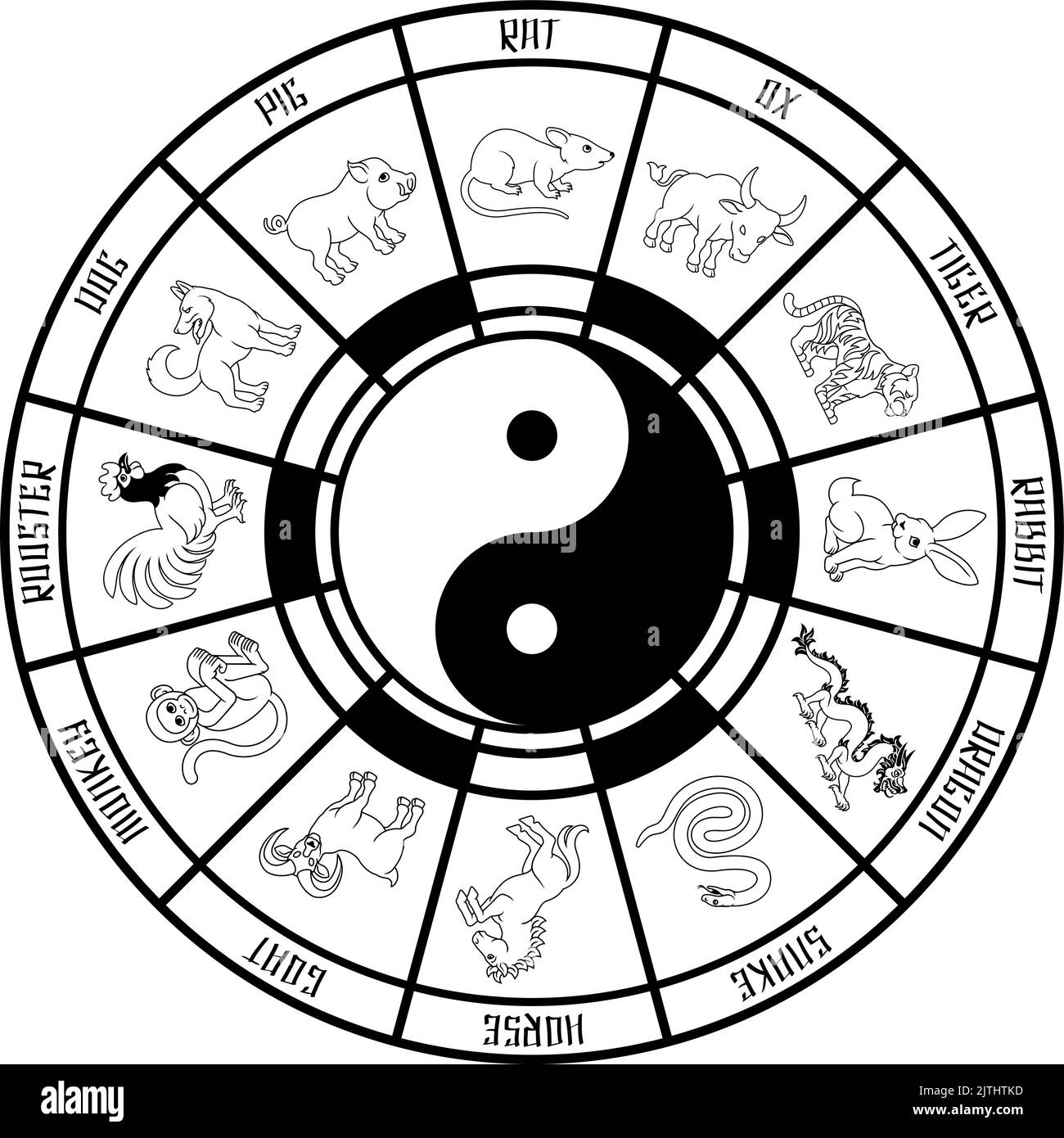

1955 Chinese Zodiac Everything You Need To Know About The Year Of The

Russian Lathe Accident Reddit